Slurry Pumps

Creative Slurry pumps are widely used to transport -Abrasive and high concentration slurry in many industries such as Gold, Silver, Iron ore, Tin, Steel, Coal, Titanium, Copper, Mineral sands, Lead and Zinc. Creative Slurry pumps are often designed to be suitable for heavy-wearing and heavy-duty uses. The selection process for centrifugal slurry pumps needs to include consideration for impeller size and design for solids passage, appropriate shaft seal possibilities and optimum, long life material selections. These basic needs to be considered by the Application Engineer who will select the suitable Pump & Material selection, to withstand wear caused by the abrasive, erosive and/or corrosive attack on the wetted materials.

To achieve lower operating speeds, Creative slurry pumps are also generally larger in size, comparable with clear liquid pumps in order to reduce velocity, thereby minimizing the rate of wear. Bearings and shafts also need to be much more rugged and rigid.

General Applications :The pumps find application in the Mineral Processing industry for transferring highly abrasive, corrosive slurry like Iron ore, Copper, Gold, Zinc, Lead, Chromite, Phosphate Ores & Ash Slurry.

Slurry Pumps also find application in

- Ore beneficiation plants

- Effluent treatment plants

- Sand beneficiation plants

- Plywood industry

- Sugar industry

- Paper and pulp industry

- Glass and Picture Tube industry and many other applications where pump has to handle the solids.

CHD ‐ CCW models provide long hours of reliable operations suitable for tough / abrasive slurries like gold, iron ore, chromite ore, zinc, aluminum and ash slurries etc. Our pump can handle up to 70% solids on weight basis and 35% on volume basis.

| Duty Parameters | |

|---|---|

| Capacity | 5 ‐550 m3/hr |

| Head | 6 to 60 mts |

| Discharge Dia | 25mm to 200mm |

| Material of Construction | Nihard, Hichrome & Rubberlined |

| Hardness | 550 to 650 BHN |

The Pumps can be offered with Gland sealing arrangement or with Expeller version as per Customer requirements.

Creative Split Double Casing Pumps are designed for handling highly abrasive slurry with slide back facility. Slide back design makes maintenance easy as the pump base slides back on the rails for replacement of impeller & gland parts without disconnecting the suction discharge connections. The pumps are designed with replaceable liners and low speed with high efficiency. Bearings are designed for more operating hours.

| Duty Parameters | |

|---|---|

| Capacity | 5‐3000 m3/hr |

| Head | 5 to 70 mts |

| Discharge Dia | 25mm to 350mm |

| Material of Construction | Nihard, Hichrome & Rubberlined |

| Hardness | 550 to 650 BHN |

The Pumps can be offered with Gland sealing arrangement or with Expeller version as per Customer requirements

General Purpose Pump For Tough Applications Design The shaft and bearing assembly unit is easily replaceable and is adjustable to maintain optimum clearance between impeller and inlet. The standard pump is outfitted with a packed gland shaft seal but can easily be fitted with a me-chemical or dynamic seal. The pump can also be supplied with a “Floating Seal”, which is virtually doesn’t require any maintenance and requires extremely minimum volume of sealing water.

| Duty Parameters | |

|---|---|

| Capacity | 150 - 800 m3/hr |

| Head | 10 to 80 mts |

| Discharge Dia | 100 mm to 200 mm |

| Material of Construction | Nihard, Hichrome |

| Hardness | 50 to 650 BHN |

The Pumps can be offered with Gland sealing arrangement

SERIES PUMPING APPLICATION ( ASH SLURRY PUMPS)

The CREATIVE Heavy Duty Slurry Pumps are designed for the toughest applications in the Mineral Processing Industry. The excellent hydraulic design guarantees maximum efficiency. Based upon the AH series pump, the CHPP series high pressure pump offers the same features and benefits as the AH pump, including identical hydraulics at up to 400-650 psi (28 - 45 kg/cm2)

The high pressure capability allows the user to operate several pumps in series(2 to 4 Pumps), all consolidated into one pump house.

- Multi-stage high pressure Pump Casings can operate upto - 400-650 psi (28 - 45 kg/cm2)

- Ductile iron fully lined casing provides durability, strength, safety, and long service life.

- Large diameter, slow turning, high efficiency impellers designed to achieve maximum wear life and low operating costs.

- Large, open internal passages reduce internal velocities, maximize wear life and lower operating costs.

- Minimal shaft/impeller overhang reduces shaft deflection and increases packing life.

- Grease or oil lubricated bearing options offer ease of maintenance and reduced downtime.

Note: Models & Dimension are prior to change according to R&D developments in the firm without any notification

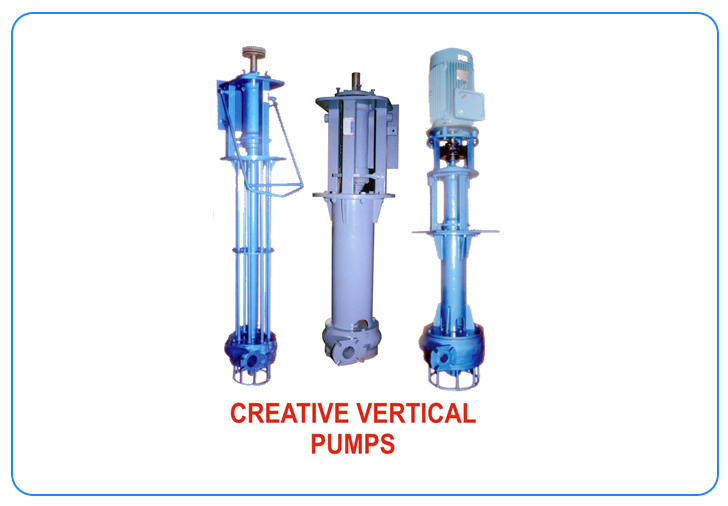

CVP - Vertical Semi - Submersible Sump Pumps

Creative vertical pumps are widely used in spillage applications in beneficiation plants. These pumps have no gland box, submerged shaft seals or bearing. This eliminates requirement of sealing water, guarantees minimum maintenance. The bearings are fitted above the sump level with having double protection against penetration of slurry. The Pump can either be fixed on a permanent basement on the railing (or) it can be overhung with a help of a chain pulley block arrangement.

TYPE 1 Standard pump with closed impeller and extended suction(inlet)

Type2 Pump with spray hole casing, semi open impeller, spray hole in the casing helps part of slurry, pumping back to the sump, to agitate settled solid in the sump.

Type3 (Pump with agitator) Ni‐hard, Hi‐chrome, Natural Rubber, CD4MCU, SS316, CF8M etc.

WEAR PARTS Agitator is attached to the extended shaft which helps to agitate coarse solids settled in the sump. More suitable for pumping coarse rapid settling solid like iron ore, coal, gold, chromite ore etc.

| Capacity | 5‐600 m3/hr |

| Head | 5 to 55 mts |

| Discharge Dia | 25mm to 200mm |

| Frame Size | 40, 60, 80, 120, 150, 180, 220 cms |

Vertical Forth Pumps With Integral Conical Tank

Pump are designed with integral conical tank pump ability to pump Frothy liquid. Conical tank with tangential inlet design works with hydrocyclone principle to separate Air bubbles from the frothy liquid. This helps efficient pumping of frothy liquids in higher capacities with long trouble free smooth operations. The M.S. Conical tank with Pump and motor are mounted on the floor with no special foundations or alignment.

Pump has no gland, submerged shaft seals or bearings. This eliminates requirement of sealing water & guarantees minimum maintenance. The bearings are fitted above the sump level, having double protection against penetration of slurry.

| Capacity | 5‐400 m3/hr |

| Head | 30 mts |

| Discharge Dia | 25mm to 200mm |

WEAR PARTS Ni‐hard, Hi‐chrome, Natural Rubber,CD4MCU, SS316, CF8M etc.

Note Models & Dimension are prior to change according to R&D developments in the firm without any notification