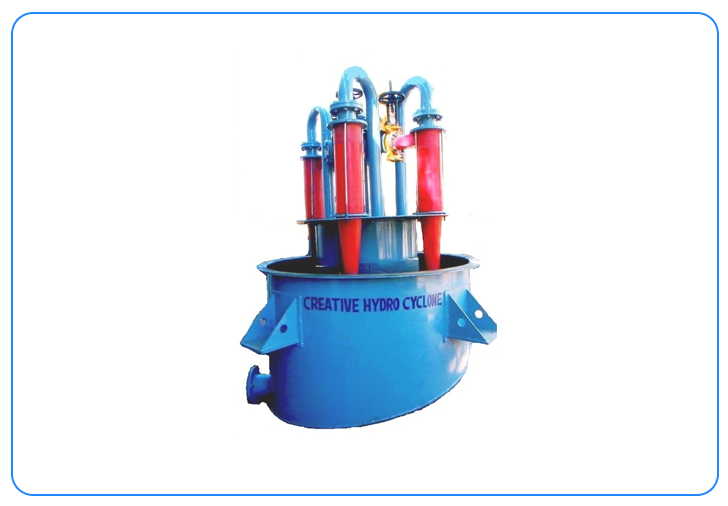

Hydrocyclones / Spearators

A hydro cyclone is a device to classify, separate or sort particles in a liquid suspension based on the ratio of their centripetal force to fluid resistance. This ratio is high for dense (where separation by density is required) and coarse (where separation by size is required) particles, and low for light and fine particles. Hydro cyclones also find application in the separation of liquids of different densities.

Hydro cyclones are highly desired because of their:

- Reclaim valuable ores by separating light and heavy minerals such as gold, copper and iron ore from feed and tailings

- In pulp and paper mills to remove sand, staples, plastic particles and other contaminants.

- Wash and classify material easily

- Relatively Low cost

- Large capacity per unit area

- Simple Structure and High Volume

- Amenability to computerized control

Hydrocyclones have its applications to dewatering and de‐sliming mineral sands, concrete sands, iron ore fines, phosphate rock and coal washery fines in mineral processing plant for classification and beneficiation.

Hydro cyclones are highly desired because of their :

- Reclaim valuable ores and heavy minerals such as gold, copper and iron ore from old tailings

- Wash and classify coal

- Relatively Low cost

- Large capacity per unit area

- Simple Structure and High Volume

- Amenability to computerized control

Hydrocyclone has an open apex permitting continuous underflow discharged to the atmosphere

CONSTRUCTION OF HYDROCYCLONE

The slurry is feed tangentially into the feed chamber at sufficient pressure to support the vortex action of the slurry in the unit. Centrifugal forces in the vortex throw the coarser particles to the wall of the cyclone body where they collect and pass downward and out through the apex section.

The diameter of the apex section controls the concentration of the underflow. The finer particles move to the inner spiral of the vortex and together with most of the liquid flow upward into the vortex finder and out the overflow.

Hydrocyclones are in high pressure operations. The feasibility of using large, progressive cavity pumps in conjunction with multitude hydro cyclone units is possible.

HYDROCYCLONE MODELS AND SPECIFICATION

| Cyclone size in inches | Cut size d50 microns | Through put in m3/hr | Material of construction |

|---|---|---|---|

| From 2 to 28 inches | 4-8 upto 60-150 | 3-4 upto 450-500 | Molded polyurethane & in Hi-chrome |

Note Models & Dimension are prior to change according to R&D developments in the firm without any notification

Creative Hydrocyclone Benefits

- High volume capacity

- Finer, sharper particles separation at high capacities

- No moving parts & hence extended wear life of liners

- Creative Cyclones can be retrofitted into existing installations to boost throughput and /or produce finer separations

- Operates at lower cyclone inlet pressure